Roque Sanchez at 2009 Solar Decathlon

At the end of day five, the Rice Solar Decathlon team is in third place behind Team Germany and Team California. The Rice entry tied for first in the hot water category, and came in second for both architecture and market viability. For updates on scores, visit the Solar Decathlon website.

Today, on the National Mall, in front of the Museum of Natural History, there’s a house built by Rice students. It’s one of 20 entries in the Solar Decathlon, a Department of Energy-sponsored competition to build a highly efficient yet livable solar-powered house. I came to DC for the installation as the structural engineer for the house.

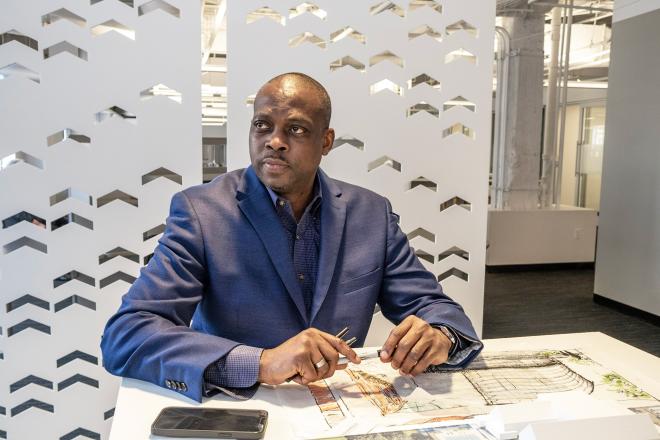

But of the Rice team there, I was probably the one who’d done the least work on it. Roque Sanchez, for example, has been working on this house for four years. He was a freshman at Rice when he started putting together the application to the competition; he graduated with a degree in Environmental Engineering in May. Nearly everything on this house was done by the students --- the architectural design (lead by David Dewane, architecture grad student), the selection of mechanical systems, the framing, the roofing, the finish work, the fundraising, communications (lead by Allison Elliot), and even the media relations (with Rebecca Sibley repeatedly interviewed by reporters). And the faculty advisers --- Danny Samuels and Nonya Grenader from Architecture, and Brent Houchens from Engineering --- kept a watchful eye on everything.

Wednesday, September 30, 11:00 pm. The mall is empty except for yellow tape marking the construction plots, but teams are gathering in the dark. It’s officially time to begin. A line of U-Hauls and flatbed trucks waits in the distance, bearing supplies and piece of houses. Team Missouri, on the plot next to us, has their truck pull in with the body of their house at 12:30. Our U-Haul is further back in line; it doesn’t reach us until midnight. Then it’s time to pull out planters --- the “green wall” that will cover the front off the house --- and boxes of tools. We also wheel over the generator a rental company dropped off for us.

Meanwhile, other teams are working away. Pieces of houses are appearing all around us. Different teams have different approaches. Missouri is driving theirs in place, then jacking it off of the flatbed. Team North, on the other side of us, is lifting the core of their house in one piece, then assembling the rest from smaller sections of floor, roof, and windows. The Spanish team built their house in three nearly finished pieces, each the trailer part of a tractor-trailer; the first piece drives in by 1:45 and its tractor detaches.

The Rice house will lift in one piece. But that won’t happen until daylight. Before then, though, we need to place the foundations, big steel pads that will sit on a layer of sand atop the grass of the Mall. They’re on our second truck; it arrives at 2:00. The students keep unloading in the early morning darkness. That takes a while, and so does placing the foundation. After a few tries, the pads are in the right place and leveled, with a steel jig setting the distances between them to an accuracy of a fraction of an inch. By then, it’s 5:00 am, and the subway is about to start running. I trudge to the station. The students are still working.

Our lift is scheduled for 10:00 the next morning. I make it back out, heavily caffeinated. The mall is now a construction site --- generators humming, power tools everywhere, seven big cranes framing the view of the Washington Monument. Our crane is there --- it actually showed up the night before and spent the night parked in front of the Smithsonian Castle. The house is there, too, but it’s deep back in a line of trucks, blocks away. I check the foundation again --- relieved that it looks fine in daylight --- and walk to the house. There are two students on the roof when I show up, mounting angles that will carry solar panels. We also remove the plywood that’s been covering the windows. Inside, the house shows no sign of its 1,400 mile trip: the sheetrock is not cracked, the kitchen cabinets are in place. With the plywood gone, it feels like a nice place to live, even on the back of a truck.

The logistics of this project cost as much as the house: trucks, cranes, flights, hotel rooms. A professional logistics firms hired the trucks, cranes, and crews and pulled all the permits.

Finally, we get the call: we’re cleared to move. The driver starts the engine. Then, another call: the crane company forgot the spreader bar in Baltimore. We can’t lift without it. And there isn’t another one nearby. So we wait again. Pizza gets ordered for lunch; everyone gathers around the disassembled pieces of the future front porch eating, then nearly everyone leans back for a rest.

The spreader bar finally shows up around 3:30. Our house gets pulled around. The crane crew strings rigging together, the crane operator and the truck diver discuss where to pull the house up to so it won’t hit trees, and the event safety coordinators hover nervously.

Our project depends on this lift. We’re the only team that’s lifting a complete house in one piece. If this works, we go from lagging behind the other teams to leading. We don’t want to think about what happens if it fails. The Missourians next door are skeptical.

The truck is in place. The crane is hooked up. Team members stand back and spread out to keep the tourists away. The crane revs up. Daylight appears under the living room end of the house. More daylight --- but the bedroom end hasn’t lifted yet. The house is suspended off kilter. This is not unexpected --- we know from the crane lift in Houston that the center of gravity is not at the center of the house --- but it dictates an adjustment. The house is set back on the truck and more shackles are added to the rigging.

The crane lifts again. This time the house is dead level. (Danny Samuels confirms with a level.) The house swings over to the waiting foundation. A rigger at end end aligns it roughly; then they kneel down to line up threaded rids with waiting sleeves. For a moment, the house hangs there impatiently. “Lined up here.” “Here, too.” Another two inch drop, and the house is in place. But the crane stays on (and safety cribbing remains in place) while students connect and tighten diagonal turnbuckles that brace the foundation pads.

4:10 pm, Seventeen hours after work on the Mall started, and we have a house. Everything’s in place and everything’s level. The crane is unhooked. There’s a sign of relief, a brief moment of congratulations, and impromptu team photo. And then everyone goes back to work. There are porches to attach, a green wall to mount, electrical connections to make, paint touch-up to do, furniture to move in, pictures to hang. I’m headed back to the hotel. But the students have another 6 days of construction before then, and then two weeks of public tours. The Solar Decathlon has only begun.

For OffCite's previous coverage of the Solar Decathlon, visit Going Solar on the National Mall and $olar $avings: Are Affordable Solar Powered Houses Possible?